Industrial equipment: utility and uses of telescopic slides

Telescopic slides are currently very popular for the proper functioning of sliding doors, drawers, sliding gates, etc. They are largely professional linear slides manufactured for applications that require heavy loads without much precision.

General information on telescopic slides

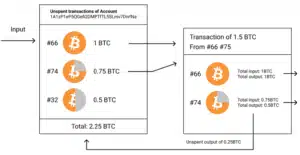

The telescopic slide is a composition of metal profiles that slide on ball bearings fixed in ball cages. It is in the form of metal rails. This material guarantees a simple and practical telescopic guidance. It sometimes consists of an inner element, a fixed outer element and an intermediate element. The latter is often provided with balls. In addition, telescopic slides are also equipped with opening and closing stops. With such an arrangement, the equipment is capable of sliding more than 1,250 kg of load over lengths of 2 m. In fact, telescopic slides promote the telescopic guidance of a heavy element around a translational swing.

Telescopic slide offered in several models

The industrial equipment market offers a range of telescopic slides. Users can choose between super extension, full extension and partial extension models. In the first case, the equipment is made up of 4 elements offering an important development with a possibility of reaching up to 2 000 mm. On the other hand, the full extension telescopic slide offers optimal development with 3 elements included. This version can withstand a weight of up to 1,250 kg with a length of up to 2,600 mm. As for the partial extension versions, there is the heavy duty telescopic slide, stainless steel and this heavy duty one. The heavy duty telescopic slide is equipped with stainless steel reinforcing balls. Thanks to these balls, the material can take back the crushing it has produced, thus ensuring safety and adaptation to its needs. Regarding the stainless steel telescopic slide, it is designed with two elements that allow it to develop around a distance of about half its closed length. This model is effective for horizontal or vertical installation thanks to its exceptional discretion and fluidity.

Criteria for choosing a telescopic slide

The acquisition of a suitable telescopic slide can be easily done based on different fundamental points. First of all, the manufacturing materials. Indeed, suppliers use a variety of materials to manufacture telescopic slides. For example, there is the slide made of formed steel. This material is very strong and is therefore used for heavy loads. There is also cold-drawn steel, which provides rigidity to the balls in the slide. On the other hand, cold drawn and hardened steel is more reliable and resistant. This material would be ideal to carry out works with materials with considerable load. In addition, the type of assembly is another essential criterion. Thus, it is important to determine the method of installation of the telescopic slide, either vertically or flat. Namely, vertical mounting involves the slides identifiable on the side part, while flat mounting involves those placed under the material to be installed. Aluminum is an excellent component for holding equipment with a lower load. In fact, aluminum is a material intended for the design of a vertical telescopic slide. Finally, you should analyze the load capacity to choose the right telescopic guide equipment. For this, you should remember that the center of gravity of the load should be placed near the rail mounted during installation. On the other hand, it will be necessary to divide the highlighted loads by 4 for the case of horizontal telescopic slides.